Emmanuel Quémener, from CBPsmn, presents his immersion cooling project. When research and transition progress in tandem.

Emmanuel Quémener, research engineer at the Centre Blaise Pascal de Simulation et Modélisation Numérique (CBPsmn - Blaise Pascal Centre for Simulation and Numerical Modeling) at ENS de Lyon, opens the doors of his computer rooms to us. This "computer test pilot" is particularly sensitive to ecological transition issues, which influence his approach to project management. As illustrated by his work on cooling immersion. To find out how research and transition progress in tandem, follow us!

Watchwords? Recycling, reusing, adapting

When managing a fleet of hundreds of machines, a good way of thinking about the ecological transition is to think in terms of carbon costs. Plural, because there are three of them: production and acquisition, provision and operation, and disposal. To recover manufacturing costs, extend the operating time and recycle equipment. The calculation sounds easy... but it isn't! Not all machine components age in the same way. So, to scrap (or even recycle) all the components of the same piece of equipment is to throw away components that can be used for many years to come. This is where Emmanuel Quémener comes in.

First stop: the machine learning room. This new collaborative room was set up with the help of the region, which financed the screens. The screens, which are difficult to transform and evolve, are the room's highest carbon cost devices. As for the rest, it's all about reuse. Under their hoods, the machines are made from computers deemed obsolete: cases, processors, memory sticks, hard disks... All working components are recovered and then recombined, with the only new component being an additional graphics card. The aim? Maximum extension of the equipment's lifespan. "With requalification processes and resilient methods, machine age is no longer an issue. This approach fulfils one of CBPsmn's missions, which is to provide a wide range of equipment, optimized for the job in hand", says our guide.

Of the 300 machines in service, 90% are significantly out-of-warranty, recovered from other units or purchased second-hand. Before closing the door, switch off the lights... and the machines. Because every little bit counts. Every morning, Emmanuel entrusts a software controller with switching on the 64 workstations in the 4 training rooms he manages. Every evening, the controller turns them off. As for stations that run continuously, our ecologically-minded computer scientist also has a solution. Since last winter, half a dozen workstations with particularly power-hungry processors, and therefore particularly hot-air generators, have been placed in offices. This year's objective is to triple this number, and it will be achieved without difficulty! Accessible by remote users, these machines become auxiliary heaters for colleagues.

What about immersing the machines?

However, this heat is an element to be managed in a data center, especially when it extends over 200 m², like the one at ENS de Lyon. The datacenter houses administrative computing, research laboratory computing and hundreds of computing servers. To prevent overheating, these machines, like our desktop computers, are equipped with radiators to remove heat from the processors and fans to dissipate it into the air. The result is higher room temperatures... and higher noise levels! No wonder we had to equip ourselves with noise-cancelling headphones. And to escape the sauna atmosphere, you'd need special, energy-intensive equipment with no guaranteed damping. For example, in the middle of summer heatwaves, 40% more energy is needed to cool the datacenter, compared with 10% in winter.

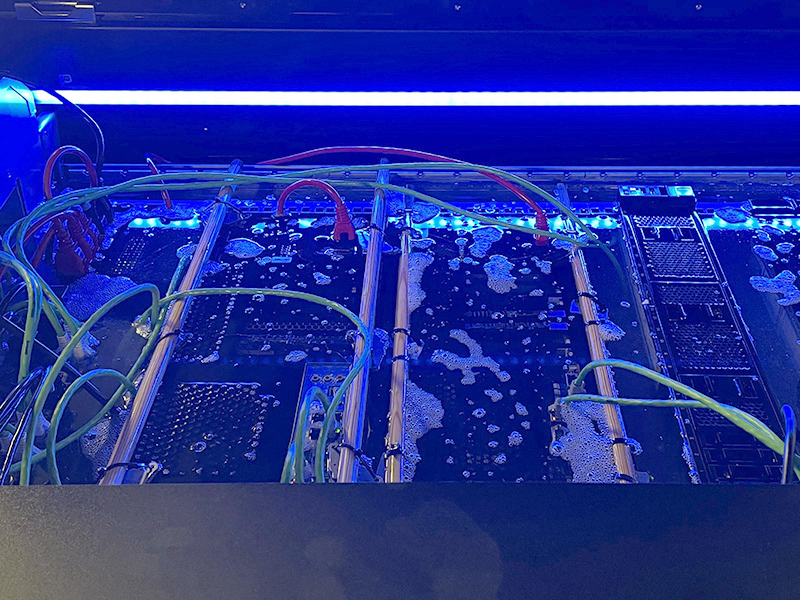

Which brings us to the end of our visit, and the presentation of Emmanuel Quémener's latest research project: immersion cooling. Here, instead of being in the open air, the machines run in mineral or vegetable oil. This process offers several advantages. There's no need for radiators or fans: the oil, which is highly heat-conductive, provides a homogeneous environment in which the machines can operate undamaged at high temperatures. This saves space, energy and longevity. This homogeneity nature limits the inter-machine disturbances that can sometimes occur in traditional data centers. Last but not least, the heat generated can be easily recovered using a water heat exchanger: hot water that's easier to cool down in midsummer, and beneficial as a supplement to the heating network in winter.

The project, carried out in a public-private partnership, is at the experimental stage. Currently, Emmanuel Quémener is working on cloned machines, to compare results between the two environments, air and oil. He is also carrying out reversibility tests, which are essential if the components are to be successfully reused. While the electronic components seem to react well, the connectors stiffen, a drawback for reuse. Massive data storage, whose disks have to spin at atmospheric pressure, would remain handled in the traditional data center. Immersion cooling would then become the machine environment for high-performance computing. The oil used, originally mineral, is now recycled frying oil, with a carbon cost considered negative! An idea that does not displease our IT research engineer.

And for those wondering whether Emmanuel Quémener's actions stop at the CBPsmn gates, extend your visit with a tour of the Descartes campus garden. Here you'll find a hedgehog hut made from machine transport pallets. If you're lucky, you may even catch a glimpse of one of the inhabitants' snout sticking out.